Tags

From the mid-1980’s through to early ‘90’s, TAG/Heuer sold a range of rather nice 200m divers watches fitted with somewhat modestly specified quartz movements from ESA.

Photo credit: http://www.calibre11.com/tag-heuer-catalogues/

Photo credit: http://www.calibre11.com/tag-heuer-catalogues/

These 1000 series divers were available in ladies and gents styles, and featured 60 click uni-directional bezels, Brevet-made cases and were available in a wide range of finishes, including straight stainless, mixed steel/gilt, all-gilt and PVD. The cases however were not unique to Heuer, being available, presumably off-the-shelf, to other brands, some well-known such as Squale and Aquastar and some much less so. Amongst the latter group, Hellas watches are a brand about which I can find nothing at all other than a suggestion that they might have been sold through mail order outlets in North America in the early 1990’s. Two new old stock examples of these Brevet cased divers found their way into my possession recently, one of which a really rather lovely ladies watch needed only a fresh battery

and the other, a mid-size gent’s watch, which, in spite of the fact that it was patently unused old stock, suffered from a number of faults requiring attention. With the comically terrible steel bracelet removed and replaced with a caoutchouc strap from Cousins, we get our first view of this attractive, modestly-proportioned watch.

and the other, a mid-size gent’s watch, which, in spite of the fact that it was patently unused old stock, suffered from a number of faults requiring attention. With the comically terrible steel bracelet removed and replaced with a caoutchouc strap from Cousins, we get our first view of this attractive, modestly-proportioned watch.

The dial is particularly nice, with tritium markers still with plenty of life left in them. The acrylic crystal, complete with cyclops over the date window to aid those long of sight, a lovely feature. The not-so-good was a movement which kept stopping, a stem clearly no where near perpendicular to the crown and which appeared to be too short in any case, making it all but impossible to return the crown to its rest position from either the time or date-setting positions. First job then is to remove the case back and take a gander at the movement, an ESA 536.121.

The dial is particularly nice, with tritium markers still with plenty of life left in them. The acrylic crystal, complete with cyclops over the date window to aid those long of sight, a lovely feature. The not-so-good was a movement which kept stopping, a stem clearly no where near perpendicular to the crown and which appeared to be too short in any case, making it all but impossible to return the crown to its rest position from either the time or date-setting positions. First job then is to remove the case back and take a gander at the movement, an ESA 536.121.

This view confirms that this is basically a Heuer 980.013 without the branding (the later TAG Heuer branded versions may have been fitted with a different movement, possibly a 555.115). My first strategy was to assume that the stopping movement was related to the wonky stem but with the crown and stem carefully realigned, and refitted the problem persisted. I resolved at this point, with nothing much to lose, to service the movement, both in the interests of fixing a problem possibly caused by a grubby movement but also because this presented me with the opportunity to service my first quartz movement. So, movement out once more, battery released

This view confirms that this is basically a Heuer 980.013 without the branding (the later TAG Heuer branded versions may have been fitted with a different movement, possibly a 555.115). My first strategy was to assume that the stopping movement was related to the wonky stem but with the crown and stem carefully realigned, and refitted the problem persisted. I resolved at this point, with nothing much to lose, to service the movement, both in the interests of fixing a problem possibly caused by a grubby movement but also because this presented me with the opportunity to service my first quartz movement. So, movement out once more, battery released

hands aligned to 12 sharp to aid their removal

hands aligned to 12 sharp to aid their removal

and with the dial off, we get a view that should be familiar to anyone who has gawped at the calendar side of an automatic ETA 2836-2.

and with the dial off, we get a view that should be familiar to anyone who has gawped at the calendar side of an automatic ETA 2836-2.

The 2836-2 and indeed the quartz 536.121 are both day/date movements but in this application, with no need for the day disk, the day corrector wheel is surplus to requirements and therefore also missing.

The 2836-2 and indeed the quartz 536.121 are both day/date movements but in this application, with no need for the day disk, the day corrector wheel is surplus to requirements and therefore also missing.

We can also see that, although the movement looks clean enough, most of the components are covered in a dried oil mist, probably the result of the watch having been in storage for 20 years or more without attention. With the rest of the calendar parts stripped off, we can flip the movement over and continue with the disassembly. The first step is to remove the coil cover

We can also see that, although the movement looks clean enough, most of the components are covered in a dried oil mist, probably the result of the watch having been in storage for 20 years or more without attention. With the rest of the calendar parts stripped off, we can flip the movement over and continue with the disassembly. The first step is to remove the coil cover

revealing the electronic module and the key components which regulate the rate of the movement.

revealing the electronic module and the key components which regulate the rate of the movement.

Next the electronic module comes off, having first removed four retaining screws,

Next the electronic module comes off, having first removed four retaining screws,

followed by what I believe ETA call the electronic module distance piece, which presumably is just an insulating spacer

followed by what I believe ETA call the electronic module distance piece, which presumably is just an insulating spacer

We can now access the train wheel bridge which provides the framework for the train wheels to transfer power from the stepper motor, driven by the coil, to the hands of the watch. The stepper motor comprises the stator made from soft iron and which houses the rotor or armature, which is a permanent magnet.

We can now access the train wheel bridge which provides the framework for the train wheels to transfer power from the stepper motor, driven by the coil, to the hands of the watch. The stepper motor comprises the stator made from soft iron and which houses the rotor or armature, which is a permanent magnet.

Each pulse from the coil magnetizes the stator, creating a magnetic field which opposes that of the permanent magnet in the rotor, causing it to rotate by 180 degrees. The next pulse, whose polarity is now reversed, completes the process by inducing a further 180 degree turn of the rotor.

Each pulse from the coil magnetizes the stator, creating a magnetic field which opposes that of the permanent magnet in the rotor, causing it to rotate by 180 degrees. The next pulse, whose polarity is now reversed, completes the process by inducing a further 180 degree turn of the rotor.

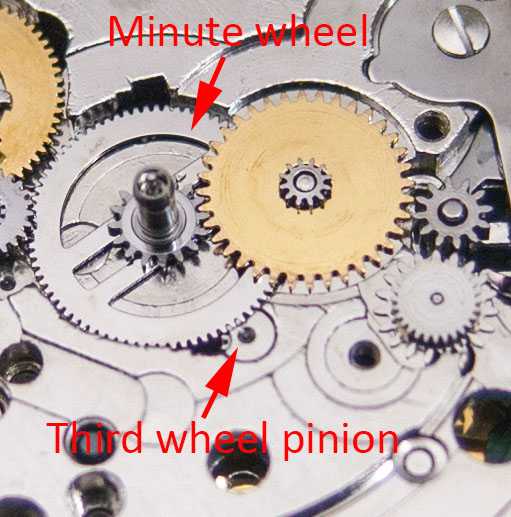

The rotation of the rotor is transferred via the intermediate wheel to the second wheel, on whose shaft is mounted the second hand. The second wheel transfers its power to the third wheel, whose pinion on its reverse protrudes through the mainplate transferring power to the minute wheel mounted on the calendar side of the movement.

The rotation of the rotor is transferred via the intermediate wheel to the second wheel, on whose shaft is mounted the second hand. The second wheel transfers its power to the third wheel, whose pinion on its reverse protrudes through the mainplate transferring power to the minute wheel mounted on the calendar side of the movement.

With the watch completely dissembled

With the watch completely dissembled

we are ready for cleaning in the ultrasonic bath, prior to reassembly, which I’ll gloss over as it’s just the reverse of what has preceded. And with no jewels to attend to, lubrication was somewhat more straightforward than with many of the automatic movements I usually deal with. However, as is often the case with me, there was one final fly in the ointment: the problem with the stem I mentioned at the start I thought I’d sorted by replacing the stem with a spare I had hanging around from an old 2824.2 project. But with the watch back together and seemingly running again, and I might add, with the stem functioning correctly, the watch kept stopping. Initially, I assumed I had somehow missed something during the service but the clue to the source of the problem emerged when I found that the watch would run quite happily with the crown unscrewed, but would stop with it screwed down.

we are ready for cleaning in the ultrasonic bath, prior to reassembly, which I’ll gloss over as it’s just the reverse of what has preceded. And with no jewels to attend to, lubrication was somewhat more straightforward than with many of the automatic movements I usually deal with. However, as is often the case with me, there was one final fly in the ointment: the problem with the stem I mentioned at the start I thought I’d sorted by replacing the stem with a spare I had hanging around from an old 2824.2 project. But with the watch back together and seemingly running again, and I might add, with the stem functioning correctly, the watch kept stopping. Initially, I assumed I had somehow missed something during the service but the clue to the source of the problem emerged when I found that the watch would run quite happily with the crown unscrewed, but would stop with it screwed down.

Perusal of Cousins’ site revealed that the 536.121 should use the ETA 2850 stem rather than the 2801 stem that I had used. A closer look at the 2801 stem (on the right, below) sitting next to the 2850 stem (left) highlights some subtle differences, small enough not to impact on the running of the watch with the stem in a neutral position, but with the crown screwed in, I suspect the stem was pressing against the movement pushing it against the inside of the case and stopping it.

So, with all now back together, a last final couple of shots of the completed watch, now running as I was hoping it would have been when originally received!

So, with all now back together, a last final couple of shots of the completed watch, now running as I was hoping it would have been when originally received!

Thank you for this post. You make even quartz movements seem sexy.

Thanks! Less of a mystery to me now than they were previously and, consequently, something to be appreciated 🙂

Hi Martin, sorry to bump this but thats what you get for writing articles that remain relevant 🙂

I noticed that the lugs on this Hella branded watch appear to be drilled whereas pics of the corresponding Heuer or Tag Heuer cases appear to not be. Is this just some sort of manufacturing variance over time or do you think the Hella case may have been drilled as a modification?

Hi Liam,

Thanks for your comment. As I understand the dynamic at the time, Brevet were supplying cases such as those featured in this post to a number of different customer watch companies, including Heuer. I imagine that there would have been some custom options which the watch companies could ask for. Hellas may either have asked for drilled lugs or simply purchased cases in this configuration as off-the-shelf items from Brevet.

Thanks Martin, I think I need to keep a lookout for one of these. A Heuer without the premium!

Hi Martin

Do you have any information on oiling points for the 536.121?

Enjoying your blog, very informative!

Ed

I don’t think I was ever able to track down the technical documents for this movement but the lubrication is pretty straightforward on the coil side (mostly 9010 on the pivots I think) and the dial side should be the same as the 2836-2 whose oiling charts you can find on the ETA website. I hope that helps.

Thanks for taking the time to respond Martin!

I’ve got some 9000 oil, so I’ll look up the 2836 chart.

Ed

9010 should be ok for the gear train but you’ll need to use appropriate oils and greases for the dial side.

Gotcha (another trip to Cousins) – many thanks!

I have a pre-Tag Heuer 981.106 (ESA movement), which has stopped running after prolonged shelf life. Do you know anybody who can work on this watch?

Bill Winter

505.321.3142

You could give Richard Askham in the UK a try.

I am so glad you got it back running. I happened to stumble on your site trolling the internet for information because I have an orange Heuer Diver 980.007 that was given to me by my grandfather a few years back, but it just stopped working about a year ago. I am so happy that I found your site because it really is amazing! My Heuer and this watch share the same movement, but no one that I have found wants to touch it, or has said “forget it parts are impossible/too expensive.” Any tips on a place to reach out for service? Thank you so much and I look forward to reading more on your blog.

Thanks Joshua. You can still find parts and even the odd complete movement but sometimes a service is all it takes. In this case though, the movement continued to be a bit temperamental with the crown screwed down and in the end I substituted it for an automatic movement (see the most recent post).

As for servicing, that depends on where you are based. If the UK, then I’d endorse either Richard Askham or Duncan Hewitt.

Hey Martin,

Thank you for the quick reply. I did read your followup and thought that was brilliant to swap it out using the ole auto you had from the Swiss Army you had around. I am actually in America (New Orleans to be exact). Sadly I haven’t found a jeweler or anyone in the area who is willing to service it (at least to the extent needed), but I am willing to ship it if you know a good place.

Thanks again!

-Josh

Pingback: Heuer pretender revisited: a quartz to auto conversion | Adventures in Amateur Watch Fettling