Tags

62MAS, Diver's Watches, Grand Seiko, Seiko, Seikomatic, Vintage

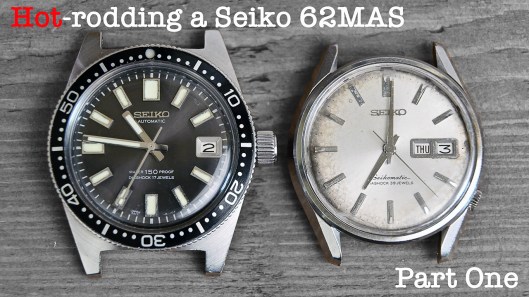

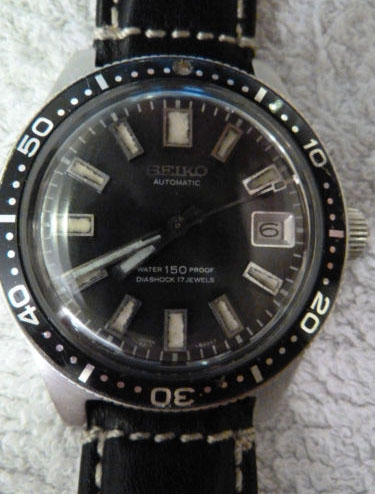

10 years ago, I bought a rather ratty Seiko 62MAS. Its movement was tired, its hour markers pock-marked with black funk and its bezel insert pretty nice but with the odd nibble along its inner diameter. In one sense perfect. 2010 was also pre-nutty inflation in vintage watch values so an amateur watch fettler could exercise a degree of latitude in deciding how to transform scruffy specimens into presentable but, crucially, wearable watches.

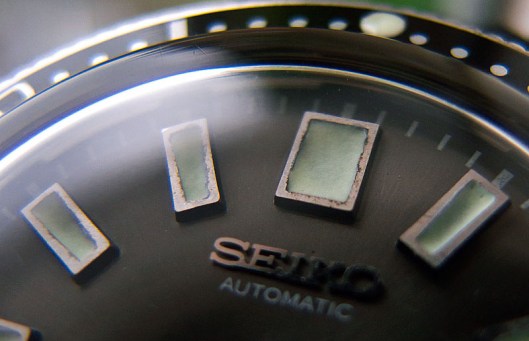

In 2011, I sent the dial, hands and bezel to be professionally relumed in the USA. The dial returned with a conspicuous scratch and competently executed relume in a poorly chosen white.

I serviced the worn-out movement and replaced the insert (for reasons that now escape me) with an excellent after-market understudy.

I wore the watch for a little while until … I could tolerate the colour and texture of the lume no more and sent the dial, hands and insert off for a professional relume in the UK. The dial returned with a second scratch but a much more period-correct colour of lume.

I was generally satisfied but the lume had been made up with a glossy binding agent and I did not like its shiny finish.

Nevertheless, I took the opportunity to replace the knackered original 6217A with a much better example.

I wore the watch for a little while until … I could tolerate the shiny lume no more and elected this time to perform a third, and hopefully final, relume myself.

Somehow, I managed to achieve a quality of colour and finish to lay to rest any concerns about the outward appearance of the watch.

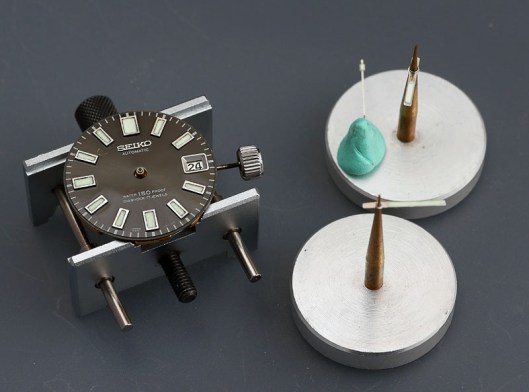

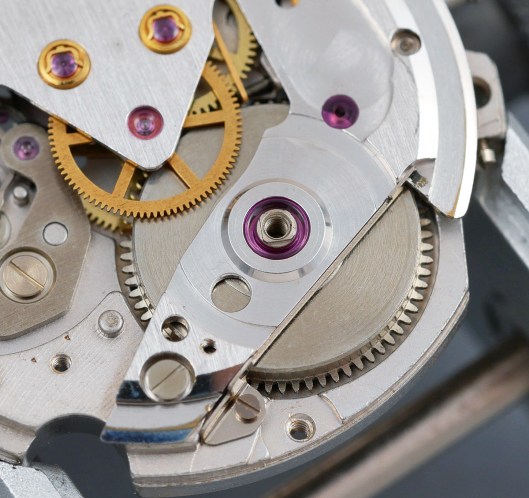

But my fiddle stick could not resist executing another permutation to the engine room. Out with the 6217A (to be put to good use elsewhere) and in with a hybrid hacking hot-rod motor, a 395/6218A/6217A Frankenstein.

While there was some enjoyment to be had in up-jeweling and up-speccing the movement, I had neglected to attend to the single biggest issue with these old 62 series movements: their vulnerability to barrel arbor hole wear in the mainplate and barrel bridge.

Here we are in the Summer of 2020, ten years into my ownership of this watch and opportunity has knocked in providing a potential solution to the engine room conundrum. A few months ago, I bought a ragged example of a Seikomatic 6216-9000.

The dial was irredeemably water-damaged but the movement looked very tidy.

And so I decided that the time had come to do what I should have done at the last iteration and install a movement with jeweled barrel arbor holes.

Rather than documenting the process in my habitual fashion, I opted to film each step in excrutiatingly tedious detail over the course of about five months and to release each part as a separate video on my YouTube channel. In reviewing my YouTube output, I now find this series of videos to represent a blot on the landscape, a misjudgement and so I have removed all traces bar a single eight minute video that captured the entire process in a more digestible form.

Martin, yet another project post that opens a window on your mind! I love to read your thinking and where your ambitious and competent tinkering takes you. Magnificent thank you, and a suitable replacement for the currently awful version of The Archers in these troubled times.

Keith

I could never have aspired to bump the Archers as a diversion and so am gratified to have achieved that milestone! Thanks for the appreciation!

Hi Martin,

Great solution to notorious barrel arbor hole wear, is there a suitable upgrade for the 6105 movements with jeweled barrel arbor holes?

My 6105-8119 required staking for the same issue.

Mel

A Grand Seiko 6146 would do the trick but there are technical challenges to overcome. Check out the ‘Hair brained scheme’ post.

Hello Martin,

My name is Dan Crandall. I am trying to fix up a Seiko 6217 and I need a mainspring barrel. I am having a hard time finding one. I was hoping you might help me out or point me in the right direction. Thanks, Take Care

Hi Dan, the part number you need is 205408. The barrel complete with arbor is shared with the 6205, 6206 and 6218 and so you could source from a junk movement if you can get your hands on one. Good luck!

Hi Martín,

I am wondering if the bezel is just popping out (like on skx Modells) oder shall I remove the insert and than the spring in order to remove the whole bezel? I don’t want to scratch the case and would appreciate some help on this. Thank you in advance

Hi Dima, the turning ring complete with bezel should be removed together using a bezel knife. It should not be too difficult and you can protect the case using a clear plastic bag. Best to work the knife around rather than twist but you will feel the best way to do it when you try. Good luck. Martin

Huge help needed. In your YouTube video (bezel, crown, crystal options) you mentioned a suitable bezel with insert option from a swiss diver that’s the same as the 62mas. Can you expand on that? Diver make and years? Like many, looking for a replacement! Thanks!

Hi Mark,

Apologies for the delay but I had forgotten the brand and had to forage to locate the donor watch. It is a Jubilee Skin Diver 666. The secret is out though and finding these for what they are actually worth, were it not for the bezel, is now very difficult.

I hope that helps

All the best

Martin

Recently I bought me a case, dial and hands of a 1966 62MAS. And I had also a 6216 lying around with no use for the movement.

But I had to modify a bit, because the date ring has to be made for the crown at position 3 o’clock. I solved that by using a date ring from a Seiko Skyliner 6222, which is the handwinder version of the 62-family. And this has the crown on 3 o’clock…

But I am aiming to get a correct movement for it, and restore it to original specs.

I wouldn’t worry too much about finding a 6217A if you can’t find one at a reasonable price. Don’t make the mistake of spending more putting together a complete parts project than you would have spent buying a complete original watch!

Don’t worry! I already found a 6217A for a reasonable price. But I can always use it for parts for my 6217-7010 worldtimer…

But I need a new seconds hand, as it is warped and damaged. There are some genuine for sale, but about €100 for a seconds hand alone? No way…

I want to restore this watch economical, not restore to all costs…

That seconds hand was used in a few other models. I’ve had a few pass through my hands over the years. So keep your eyes peeled and you will have a complete watch in addition to a donor seconds hand for hopefully less than 100 Euros!