Tags

From about 1970, Seiko introduced an approach to many of their mid case designs that made use of Hardlex tempered mineral crystals bonded into a metal frame. The frame served a dual purpose of providing the sealing surface to a complex-profiled rubber gasket as well acting as a polished inner rehaut. This design of crystal was widely used in many Lord Matics, King Seikos, Grand Seikos, 7018 chronographs and some of the early quartz models.

This was also a time when Seiko became fond of using faceted crystals whose prominent profiles made them vulnerable to chips and scratches. Replacing such crystals at service was of course no problem when spare parts were in plentiful supply but here we are in 2018, nearly 50 years after this crystal design was first introduced, and supplies are fast running out – for some of the more commonly used part numbers, they are all but exhausted.

This was also a time when Seiko became fond of using faceted crystals whose prominent profiles made them vulnerable to chips and scratches. Replacing such crystals at service was of course no problem when spare parts were in plentiful supply but here we are in 2018, nearly 50 years after this crystal design was first introduced, and supplies are fast running out – for some of the more commonly used part numbers, they are all but exhausted.

In the absence of an easily available replacement spare part, the obvious strategy must be to remove the battered old crystal from its frame and replace with a suitable alternative. This presents three problems, none of which trivially solved:

- How do we remove the crystal from its frame cleanly without damaging the frame?

- How do we identify and source a suitable replacement crystal to glue back into the frame?

- How do we glue the new crystal into the frame in a way that is as invisible as possible?

Let’s tackle all three questions in the context of the two King Seiko watches whose stories so far are recounted in the two preceding posts.

1. Removing the crystal from its frame

The crystals were originally bonded into the metal frame very securely and the passage of time does not generally appear to have compromised that security. Consequently, you cannot simply press the crystal out from the rear hoping that the ancient glue will relinquish its grip. Heat seems like one obvious strategy but there is a danger that heat alone might tarnish the metal, warp the frame or crack the crystal, the latter adding to the potential to scratch the inner surface of the frame. In my early experiments with these crystals, I did try heat but I got nowhere – either I was too conservative in my approach or this strategy was doomed to fail from the start; a bit of a head-scratcher then. What else does a typical watchsmith have in their arsenal to throw at such a problem? How about the trusty ultrasonic bath? Let’s give that a try.

An extended blast immersed in water at room temperature was a somewhat disheartening experience, the crystal seemingly still disinclined to part company with its frame. Any good experimentalist will navigate their way to the solution to a problem by changing one variable at a time and so let’s stick to the ultrasonic bath but now elevate the temperature. A repeat performance at 50°C was no more successful than at 20°C and so I cranked up the heater on my ultrasonic bath to 80°C and ran it for a good 40 minutes as the temperature slowly crept up to about 75°C. Much to my relief, I seem to have hit upon the magic formula: my first guinea pig crystal, taken from the 5626-7000, separated easily once extracted from the bath.

An extended blast immersed in water at room temperature was a somewhat disheartening experience, the crystal seemingly still disinclined to part company with its frame. Any good experimentalist will navigate their way to the solution to a problem by changing one variable at a time and so let’s stick to the ultrasonic bath but now elevate the temperature. A repeat performance at 50°C was no more successful than at 20°C and so I cranked up the heater on my ultrasonic bath to 80°C and ran it for a good 40 minutes as the temperature slowly crept up to about 75°C. Much to my relief, I seem to have hit upon the magic formula: my first guinea pig crystal, taken from the 5626-7000, separated easily once extracted from the bath.

The next step is to remove the glue residue from the metal frame but if you wait too long, the glue will harden again and its removal will be a protracted business that is much more likely to result in damage to the frame. The trick is to remove the glue while it is still warm and wet.

The next step is to remove the glue residue from the metal frame but if you wait too long, the glue will harden again and its removal will be a protracted business that is much more likely to result in damage to the frame. The trick is to remove the glue while it is still warm and wet.

At this point then, we have a clean, undamaged metal frame and so we need now to identify a suitable glass crystal to glue back in.

At this point then, we have a clean, undamaged metal frame and so we need now to identify a suitable glass crystal to glue back in.

2. Identifying a suitable replacement crystal

Both crystals from my two automatic King Seikos are 30 mm in diameter, but their frames are of different depths and profiles and incompatible with one another. The 5626-7000 takes the 300V04GNS crystal and the 5626-7111 uses the 300V16GNS. However, the glass in both appears to be of identical profile: essentially a flat top (possibly with a very subtle dome) with an inner dome and a clear polished bevel around the edge.

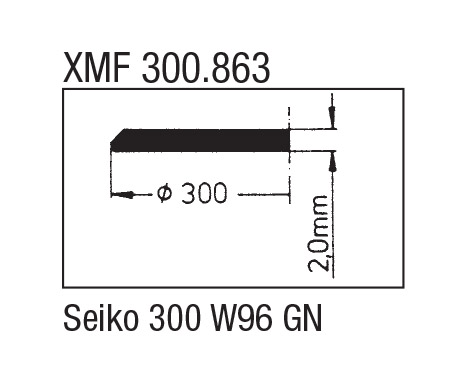

One option is simply to replace with a 30 mm flat crystal, and suitable candidates in this case could be something like one of the Sternkreuz facsimiles of the Seiko 300W19GN or 300W96GN crystals.

One option is simply to replace with a 30 mm flat crystal, and suitable candidates in this case could be something like one of the Sternkreuz facsimiles of the Seiko 300W19GN or 300W96GN crystals.

These are of different thicknesses and consequently the extent to which they will present themselves above the watch bezel will differ but either could provide a serviceable option. However, you will then lose the inner dome that, while fairly subtle in these watches, does have a noticeably pleasing optical effect.

These are of different thicknesses and consequently the extent to which they will present themselves above the watch bezel will differ but either could provide a serviceable option. However, you will then lose the inner dome that, while fairly subtle in these watches, does have a noticeably pleasing optical effect.

To my mind, a better choice is to find a domed crystal. There aren’t too many generic options but one such is the Sternkreuz MD 300, a double-domed mineral glass crystal with a frosted bevel. Not a faithful replacement but to my eye, it represents a more charismatic choice over a bog standard flat crystal.

The third and arguably best option is to find a 30 mm V-type bonded crystal that is still in plentiful supply and which contains a glass of the same profile as that used in the 300V04 and 300V16 variants. The glass from the sacrificial crystal can then be removed using the technique described above and then re-bonded back into the correct frame. This is a very labour-intensive approach which requires you to set to one side the moral dilemma of vandalizing an otherwise perfectly serviceable crystal and for this reason I hesitate to recommend it, in spite of the fact that I have taken this approach for one of our two King Seikos.

The third and arguably best option is to find a 30 mm V-type bonded crystal that is still in plentiful supply and which contains a glass of the same profile as that used in the 300V04 and 300V16 variants. The glass from the sacrificial crystal can then be removed using the technique described above and then re-bonded back into the correct frame. This is a very labour-intensive approach which requires you to set to one side the moral dilemma of vandalizing an otherwise perfectly serviceable crystal and for this reason I hesitate to recommend it, in spite of the fact that I have taken this approach for one of our two King Seikos.

3. Bonding the new crystal into the frame

This whole exercise will be utterly fruitless unless this final step can be achieved invisibly. I mean by this that it should not be possible, at least without the aid of a loupe, to discern any obvious signs that the crystal has been glued into the frame. The glue must therefore be of a type that dries clear and colourless, it must be applied evenly and there must be no signs of overspill. Of course it needs also to be water resistant and provide a secure and strong bond between glass and metal frame. I would avoid using any two-part epoxy glue – they tend not to dry invisibly and there is the danger that any unreacted hardener might leech through the joint and onto the dial. I have tried two different types of glue, both designed specifically for glass and both requiring curing under UV light.

One of these can be purchased very cheaply, the other not! Having selected our adhesive, we need to apply it. Again, I’ve experimented with a number of approaches and the one I am happiest with is to use a sharpened tooth pick to apply a thin and even layer of the glue to the upper horizontal mating surface of the metal frame only.

One of these can be purchased very cheaply, the other not! Having selected our adhesive, we need to apply it. Again, I’ve experimented with a number of approaches and the one I am happiest with is to use a sharpened tooth pick to apply a thin and even layer of the glue to the upper horizontal mating surface of the metal frame only.

Once you are satisfied that you’ve done this without contaminating the rehaut surface, press the clean crystal into the frame, working as required to even out the distribution of the glue. This is probably the most challenging part of the process to get right. Next, depending on whether you are using the superglue or the Seiko S-314, you can either cure the glue under direct sunlight or by using a UV curing lamp. The instructions for the Seiko glue suggest that you need to cure under UV light for up to an hour. The superglue supposedly requires just a few minutes in sunlight.

Once you are satisfied that you’ve done this without contaminating the rehaut surface, press the clean crystal into the frame, working as required to even out the distribution of the glue. This is probably the most challenging part of the process to get right. Next, depending on whether you are using the superglue or the Seiko S-314, you can either cure the glue under direct sunlight or by using a UV curing lamp. The instructions for the Seiko glue suggest that you need to cure under UV light for up to an hour. The superglue supposedly requires just a few minutes in sunlight.

Assuming all has gone smoothly, you will at this point have a completely assembled crystal assembly that appears, to reasonably fussy external scrutiny, largely indistinguishable from a factory replacement part. The photo below shows a new Seiko crystal harvested from another V-type frame, and bonded back into the original 300V16GNS frame from the KS 5626-7111.

Assuming all has gone smoothly, you will at this point have a completely assembled crystal assembly that appears, to reasonably fussy external scrutiny, largely indistinguishable from a factory replacement part. The photo below shows a new Seiko crystal harvested from another V-type frame, and bonded back into the original 300V16GNS frame from the KS 5626-7111.

Note the polished bevel at the edge of the glass. The second photo (below) shows a Sternkreuz MD300 crystal bonded into the original 300V04GNS frame from the KS 5626-7000. You should be able to see that this crystal stands a bit taller than the original and has a frosted bevel to the edge of the glass.

Note the polished bevel at the edge of the glass. The second photo (below) shows a Sternkreuz MD300 crystal bonded into the original 300V04GNS frame from the KS 5626-7000. You should be able to see that this crystal stands a bit taller than the original and has a frosted bevel to the edge of the glass.

Both crystals look good when viewed from the top and so I undertake to go ahead and use these now to finish off the two King Seikos. We’ll see to what extent the choice of replacement crystal works in the third and final part of the automatic King Seiko trilogy (coming soon).

Both crystals look good when viewed from the top and so I undertake to go ahead and use these now to finish off the two King Seikos. We’ll see to what extent the choice of replacement crystal works in the third and final part of the automatic King Seiko trilogy (coming soon).

Hi,

Do you recommend which type of solution to use if any to the ultrasonic watch cleaner? Or water will do just fine?

Thanks,

Btw- This is great! Thanks for all the helpful information and tips. Keep up the great work!

I just used plain water. It is the combination of heat and the ultrasonic agitation that does the trick. And thanks for the kind comment.

This is such a well presented and useful post. I have this issue at the moment and I think you have saved me a lot of time and hassle. Thank you so much martin! Richard

Thanks and no problem!

Hi Martin, this is a very helpful post. I have a KS 5626-7020 that I’m looking for a crystal. I have managed to remove the old chipped crystal from the bezel and would prefer, as you suggest, to use a 30mm V-type crystal. Do you have a suggestion as to the crystal code I could search for to find one to fit? Thanks much!

Hi Eric, the problem is that pretty much all of the 300V crystals with glass of the correct style will be equally difficult to source. You may be better off just fitting a generic beveled flat glass such as the Sternkreuz option I mentioned in the post. That is another way of saying that I do not know what code to suggest because all of them appear to be obsolete apart from those that use faceted crystals.

Hi Martin,

I manager to source a NOS 300V07GNS for my KS4502 price was horrific, but the price for buying equipment for transferring a crystal would also be high. As I don’t expect to do this again I opted for an original.

Before fitting it to the watch I want to make sure that it is clean.

What would recommend using? I am considering wiping with a small amount of IPA. Your recommendation is much appreciated.

Thanks and have a nice weekend.

Rgds. Sten

Glass cleans up really well with freshly laundered cotton but make sure to blow away any stray bits of fluff after. I tend to look through the crystal against a black background for foreign bodies.

Has anyone tried these aftermarket V crystals?

http://cgi.julesborel.com/cgi-bin/matcgi2?ref=WZkWIjcwH

That link takes you through to the Jules Borel database for the 300V05GNS but if you enter that part number into their homepage, it comes up as ‘no items found’. They have thousands of parts listed on their database that they no longer have in stock.

Great post(s) both on info and pictures! Do you by chance know the dimensions of the original crystal for the 5626-7000? Im thinking of total thickness and how thick the edge is before the bevel starts. That would be of great help!

Thanks again!

Hi William,

I’ll try and take a measurement tomorrow. Glad you found the post helpful.

Hi William,

I was able to take some approximate measurements this morning. They are as follows:

Diameter at base: 30mm

Diameter of top: 28.4mm

Height to top of bevel: 1.9mm

Height of crystal at centre: 2.25mm (the crystal has a slight curve and so higher at the centre than at the edge.

I forgot to measure the height before the bevel starts but estimate that it is about half way – maybe 1 mm.

All the best

Martin

Hi Martin,

You did a pretty nice job here, and again I am so lucky finding your blog. As you remember I started to clean my 5626-7000 and just wanted to have a look at the movement because there were no movement shot on ebay. The watch has genuine parts looked nice but the movement?

So I opened it, and the movement is beautiful.

And as cleaning the bezel and the glass… The glass came off. So I removed the glue instantly and was thinking what to do and just read this article… So here’s the good example, I carry on.

Thank you again for this good chance to learn.

Regards,

Istvan

I’m glad you found it helpful Istvan.

Thank you.

I also checked the casing guide but there is no reference for the dial. If I try the impossible, what ref should I look for the 7000 dial?

Thanks,

Istvan

I recently got a very cheap Lord Matic with a badly scratched faceted 300V62GCS, otherwise in good condition, and decided to swap the crystal for new flat one. I remembered reading this, but was afraid that my tiny ultrasonic cleaner might not be up to the task (and it doesn’t have heating anyway), so first I tried a simple soak in acetone.

After some 24 hours, the glass popped right off and the glue could be easily cleaned before it dried and hardened (and if it does, you can just soak it again). It took some time, but is probably a good option to consider if you don’t have the equipment.

Thanks for sharing your experience. Worth a try certainly but of course take care handling unpleasant solvents such as acetone!

Hello Martin,

Congratulations for the wonderful jon you’ve done here.

I also have 2 KS and I was thinking to replace the glasses too.

Since the original seems to be no longer available, and whatever replacement would not be coeval anyway, a this point I was considering to put a stronger glass such a sapphire.

Have you thought about this option? If yes, have you found any sapphire that could fit and you’d like to share infos about?

Thank you in advance

Hi Gabriele, I did give sapphire consideration but none of the generic sapphires I’ve seen have a tapering bevel – just squared off edges and none with the slight dome of the originals. But if there was something of a suitable profile, then I’d certainly give it a try.

Hi,

Not sure if it helps, but I’ve found that ebay seller, who is actually selling KS replacement glass. I’ve just contacted him to know if he has a reference table, or a list of compatible models.

https://www.ebay.com/itm/154266373100

Thanks Guillaume. I have some samples of those crystals and they look very good but I have not yet tried them. Hopefully I will get to one of my other numerous KS projects soon to give them a try.

Hi Martin, I assume the serial no. is more or less arbitrary and that the other designations indicate the fit and finish. Is that right? and how do you do an exhaustive search if you have an arbitrary production number in the middle ? Anyhow I like your method for reusing that metal frame.

If we take the crystal code 300V16GNS as an example: the 300 signifies a diameter of 30.0mm; V signifies a metal ring; the next two digits the serial number but I guess that is just sequentially assigned and carries no other meaning; G means Hardlex glass; N means ordinary finish to the glass; and S to silver colour to the metal ring to match a steel cased watch. As to compatibility, that is just a case of trial and error.

I’m back once again to thank you for being an invaluable resource for us.

I consulted the three options and decided on a variation that may be of interest to you. I received a MD Sternkreuz 285 to replace one of those extinct fancy cut crystals for an LM special. I figured it would retain some of that showiness. The frosted bevel really dont look right to me so I went for bust. I picked up a mini lathe, fitted a holder, and polished the bevel to a high polish with Cerium Oxide. I didn’t take long after some experimenting, although it wasn’t the most relaxing task. I’m very satisfied with the result. The edge from bevel to top isn’t as sharp to the touch as pre-polished however it looks sharp to the eye and intentional after fitting. Anyhow, your blog was once again a critical stop along the way so for that, thank you.

Hi Wolfgang, I felt the same about the frosted bevel of the crystal I fitted to one of my KS and so it is good to hear of your success with cerium oxide polishing. Well done!

Yes, I’ve had success polishing out the frosted bevel on these MD crystals. I used a flat emery stick that I endeavored to keep parallel to the bevel face by eye, as the glass was rotated in a make-shift chuck. I fear a very slight curvature was inflicted upon the slope of the bevel, judged from reflections. Still very presentable, at least on mid-market pieces like Lord Matics, and Actus.

The fact that we can polish out suggests, (as does its price), that this glass is not surface hardened like Hardlex though.

Hi Martin,

Many thanks for your blog post. I’ve learned a lot by reading both the post and comments below!

Any idea if a NOS 300V04GNS is able to fit a 5625-7040? I’m slightly confused, as some users on other sources mentioned the correct crystal would be 300V04GN, but the “S” at the end denotes a metal ring in silver colour, which is essentially what I’m looking for!

Thanks again!

Scott

Hi Scott, the correct crystal part number for your watch is 300V04GNS. Indeed the S at the end signifies silver colour. There are gold plated model variants that accept this crystal but for which a gold coloured frame would be required in in that case the reference would have a G at the end.

Many thanks for your prompt response and great help, Martin!

Scott

This was very helpfull, and I replicated your method. It works!

But I can give a suggestion for the crystal, take a Verlux 300.863, because it has the shiny bezel and looks about the same as the original.

As far as I can tell, the Verlux 300.863 is the same as the Sternkreuz XMF 300.863, both of which are supposed to be reproductions of the Seiko 300W96GN crystal. This is one of the options that I suggest in the article. However, this crystal is flat on both interior and exterior faces and fails to duplicated the slight inner dome of the correct original crystal. But of course, everyone’s mileage may vary and I have certainly found the 300W96GN to be an acceptable choice.

Just glued in a Sternkreuz, but I read something interesting on the label of the Sternkreuz UV-Glue I used: If you want to remove the crystal, just cook the glas.

That would mean, the ultrasonic isn’t really necessary. It will help, no question, but for those who don’t have a ultrasonic cleaner, here is a solution!

And I found out, the old glue could be removed with ethanol. Worked for me!

I’ve tried all sorts in the past including solvents and submerging in boiling water and the only way that works every time for me is hot water and and extended period in an ultrasonic bath. You mileage may vary depending on the extent to which the integrity of the old glue has been compromised. But all worth a try.

Hi Martin.

I am rather new to this came but during the last 2 years, I’ve been using your blog/posts regularly.

I find it so much easier to follow your service and service advice than any Youtube channel.

So, I just like to say thank you for your effort. It has really been useful for me.

Kindly, Rune

Thanks Rune, I’m very happy to hear that you have found my posts useful and appreciate your feedback. All the best Martin

Martin. This is simply excellent. Keep up the great work. Kind regards. Chris

Thanks Chris. I’m pleased to hear you find it useful!