Tags

It is generally accepted that the death knell for the mainstream mechanical watch sounded in 1969 with the introduction of the world’s first quartz wrist watch, the impossibly exotic and fearsomely expensive 18K gold Seiko Astron.

However, the twinkle in the eye of that death knell sounded 11 years previously with the introduction, possibly prematurely, but introduction nevertheless, of the Hamilton Ventura electric wristwatch. The idea that electrical energy might be used to power a watch seemed at the time an astoundingly futuristic technological concept. The impact of the Ventura was compounded by its revolutionary asymmetric case design but its commercial success was undermined by reliability issues and the challenges that its complexity presented to watchmakers in repairing and servicing the movement.

However, the twinkle in the eye of that death knell sounded 11 years previously with the introduction, possibly prematurely, but introduction nevertheless, of the Hamilton Ventura electric wristwatch. The idea that electrical energy might be used to power a watch seemed at the time an astoundingly futuristic technological concept. The impact of the Ventura was compounded by its revolutionary asymmetric case design but its commercial success was undermined by reliability issues and the challenges that its complexity presented to watchmakers in repairing and servicing the movement.

The landmarks that bridged the gap between the first electric watch and the first quartz watch followed thick and fast, so much so that Hamilton found themselves overrun in the technological stakes. Just a year after the Ventura was released, LIP introduced the world’s first watch to employ an electronic component (a diode to reduce sparking) and then two years later in 1960, Bulova Introduced the famous Accutron ‘Hummer’, the first watch to employ a transistor, and therefore the first electronic watch. ESA’s Dynotron movement of 1968 is widely credited as the first to employ a balance wheel and a transistor but there is a more than credible case that in fact Citizen were the first to that landmark in the commercial release in 1966 of the Cosmotron, ‘the world’s first genuine electronic wristwatch that has adopted a moving-magnet type balance motor, driven by transistor on the regulating device’.

The landmarks that bridged the gap between the first electric watch and the first quartz watch followed thick and fast, so much so that Hamilton found themselves overrun in the technological stakes. Just a year after the Ventura was released, LIP introduced the world’s first watch to employ an electronic component (a diode to reduce sparking) and then two years later in 1960, Bulova Introduced the famous Accutron ‘Hummer’, the first watch to employ a transistor, and therefore the first electronic watch. ESA’s Dynotron movement of 1968 is widely credited as the first to employ a balance wheel and a transistor but there is a more than credible case that in fact Citizen were the first to that landmark in the commercial release in 1966 of the Cosmotron, ‘the world’s first genuine electronic wristwatch that has adopted a moving-magnet type balance motor, driven by transistor on the regulating device’.

Seiko’s entry to the electronic watch market appeared to lag slightly behind their main domestic rival but that is probably because they were keeping their powder dry, devoting considerable resource throughout that decade to the development of the Astron quartz watch. Nevertheless, in 1967, they joined the electronic watch fray and by 1969 the El-370 Electronic Series was being actively marketed in the USA as “Up to the minute watches for the man who looks to the future”. These watches featured the 3700 series of transistorized balance movements and played a stopgap-role during the period in which the new quartz technology was finding its feet. The EL-370’s lasted until about 1974 when they were replaced by the Elnix series of electronic balance watches, featuring the last iteration of Seiko’s take on the transistorized balance movement, the 0703A.

Seiko’s entry to the electronic watch market appeared to lag slightly behind their main domestic rival but that is probably because they were keeping their powder dry, devoting considerable resource throughout that decade to the development of the Astron quartz watch. Nevertheless, in 1967, they joined the electronic watch fray and by 1969 the El-370 Electronic Series was being actively marketed in the USA as “Up to the minute watches for the man who looks to the future”. These watches featured the 3700 series of transistorized balance movements and played a stopgap-role during the period in which the new quartz technology was finding its feet. The EL-370’s lasted until about 1974 when they were replaced by the Elnix series of electronic balance watches, featuring the last iteration of Seiko’s take on the transistorized balance movement, the 0703A.

The Elnix model line appeared in the 1974, 1975 and 1976 domestic Seiko catalogues but by 1977, all traces had vanished.

Indeed, it is difficult to find any reference at all to the electronic watch in official Seiko historic timelines, although examples of an EL-370 and Elnix are on display at the Seiko Museum in Tokyo.

Indeed, it is difficult to find any reference at all to the electronic watch in official Seiko historic timelines, although examples of an EL-370 and Elnix are on display at the Seiko Museum in Tokyo.

This extended preamble brings us finally to the subject of today’s adventure: A Seiko Elnix 0703-7010 dating from March 1974 and resplendent in its outrageous 1970’s colour scheme of vibrant green, mixed gold and chrome highlights and even a splash of red into the bargain. Not content with flamboyant colouring, this particular watch also sports a multifaceted crystal standing erect and proud, although in this instance, bearing the scars of at least some of the 43 years that have passed since it emerged from the Daini factory in Tokyo.

This extended preamble brings us finally to the subject of today’s adventure: A Seiko Elnix 0703-7010 dating from March 1974 and resplendent in its outrageous 1970’s colour scheme of vibrant green, mixed gold and chrome highlights and even a splash of red into the bargain. Not content with flamboyant colouring, this particular watch also sports a multifaceted crystal standing erect and proud, although in this instance, bearing the scars of at least some of the 43 years that have passed since it emerged from the Daini factory in Tokyo.

I actually had no intention of buying this watch but it came in a job lot of three watches, one of which had caught my eye and the lot attracted sufficiently little attention that mine was the winning bid. Somewhat to my surprise though, it was the Elnix that ended up pushing my buttons a little more than the other two. So here we are in completely unfamiliar territory, in marked contrast to the comfort zone of our previous post.

I actually had no intention of buying this watch but it came in a job lot of three watches, one of which had caught my eye and the lot attracted sufficiently little attention that mine was the winning bid. Somewhat to my surprise though, it was the Elnix that ended up pushing my buttons a little more than the other two. So here we are in completely unfamiliar territory, in marked contrast to the comfort zone of our previous post.

Externally, the watch has a lustre of ‘used but well cared for’ with no signs externally that it has been abused in any way. Freed from its bracelet, the Elnix presents its obvious 1970’s styling credentials with some brio.

The positivity exuded by its external face was quickly undermined on taking a look under the lid. With its somewhat ancient battery removed, it is clear we have an(other) electrolyte spillage on our hands.

The positivity exuded by its external face was quickly undermined on taking a look under the lid. With its somewhat ancient battery removed, it is clear we have an(other) electrolyte spillage on our hands.

The crusty state of the movement distracts momentarily from the conflicting visual cues: on the one hand, this is clearly a movement that exploits electrical energy as its power source and yet there too clearly a balance, albeit one of rather more robust construction than we are used to.

The crusty state of the movement distracts momentarily from the conflicting visual cues: on the one hand, this is clearly a movement that exploits electrical energy as its power source and yet there too clearly a balance, albeit one of rather more robust construction than we are used to.

Extracting the movement from the case requires the stem release button to be located. Nothing obvious presents itself until the crown is pulled out at which point the release lever emerges into view.

To the best of my knowledge, no technical documents exist for the 0703 (or at least none are in circulation) and so I will be flying blind from this point. I do have a technical guide for the predecessor 3703A but the two movements share no parentage and the layout is quite different. Looking at the two designs, the 0703A looks by far and away the better resolved of the two, a matured technology rather than one in flux. So, let’s get to it. Setting the movement onto a case cushion, we can appreciate the very nice state of the dial and handset.

To the best of my knowledge, no technical documents exist for the 0703 (or at least none are in circulation) and so I will be flying blind from this point. I do have a technical guide for the predecessor 3703A but the two movements share no parentage and the layout is quite different. Looking at the two designs, the 0703A looks by far and away the better resolved of the two, a matured technology rather than one in flux. So, let’s get to it. Setting the movement onto a case cushion, we can appreciate the very nice state of the dial and handset.

With the hands off, we need to determine how the dial feet are secured to the movement. A quick scout about to the rear and we see that the two feet are held in place by a pair of eccentric screws. Rotating each by 180 degrees anti-clockwise frees the feet from their shackles.

With the hands off, we need to determine how the dial feet are secured to the movement. A quick scout about to the rear and we see that the two feet are held in place by a pair of eccentric screws. Rotating each by 180 degrees anti-clockwise frees the feet from their shackles.

I think the first step should probably be to remove the stop switch lever followed by the circuit block, which in contrast to the earlier 3703A, is a separate component.

I think the first step should probably be to remove the stop switch lever followed by the circuit block, which in contrast to the earlier 3703A, is a separate component.

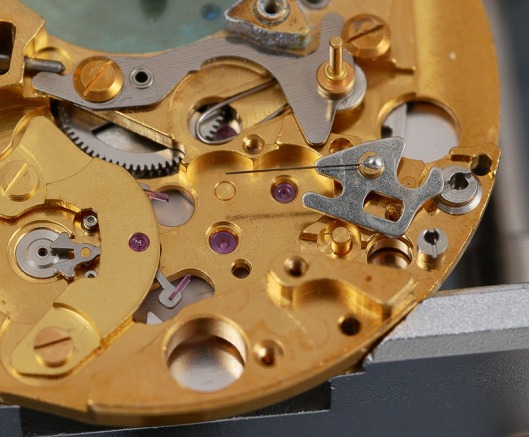

The removal of the circuit block affords a much clearer view of the coil and balance assemblies.

The removal of the circuit block affords a much clearer view of the coil and balance assemblies.

It is probably worth describing at this point the operation of these movements now that we have sight of the key components. All transistorised movements employing a balance work on the same principles and in doing so operate in a way in which the train wheels are driven in the reverse sense to a conventional mechanical movement. Where a mechanical movement employs a mainspring as its source of power with the escapement acting to regulate and measure out that power to the gear train, in an electronic watch, it is the balance itself that drives the movement as a result of the interplay of magnets located on a pair of parallel balance wheels and a pair of fixed coils sitting between the two wheels.

It is probably worth describing at this point the operation of these movements now that we have sight of the key components. All transistorised movements employing a balance work on the same principles and in doing so operate in a way in which the train wheels are driven in the reverse sense to a conventional mechanical movement. Where a mechanical movement employs a mainspring as its source of power with the escapement acting to regulate and measure out that power to the gear train, in an electronic watch, it is the balance itself that drives the movement as a result of the interplay of magnets located on a pair of parallel balance wheels and a pair of fixed coils sitting between the two wheels.

Rotation of the balance causes the magnet to move across the coil, inducing a current in the primary coil and the transistor completes the circuit to the second induction coil. The balance then receives an impulse kick as a result of the induced magnetic field. As the balance swings back, the primary coil generates a reverse current and the transistor breaks the circuit. The crucial development employed in these movements over earlier electric balance driven watches was that the transistor acts as a switch without the need for physical contacts and the problem that can result from wear caused by sparking.

Rotation of the balance causes the magnet to move across the coil, inducing a current in the primary coil and the transistor completes the circuit to the second induction coil. The balance then receives an impulse kick as a result of the induced magnetic field. As the balance swings back, the primary coil generates a reverse current and the transistor breaks the circuit. The crucial development employed in these movements over earlier electric balance driven watches was that the transistor acts as a switch without the need for physical contacts and the problem that can result from wear caused by sparking.

The fact that the coil sits between the two balance wheels means we need to exercise a degree of care in extracting the two from the movement. The balance cannot be removed before the coil is out but it is easier to remove the coil if the balance is no longer fully secured to the movement. I found it easiest to remove them together with some concerted cooperation to avoid damaging the delicate coils. In the photo below you can see the coil partially swung out from between the two balance wheels.

Here we see the balance more clearly with its strange parallel pair of wheels.

Here we see the balance more clearly with its strange parallel pair of wheels.

With the balance and coil safely out of the way, we can inspect the escapement. The reversed direction of operation of the movement means that the job of the pallet and escape wheel is not to measure out the power from a mainspring via the balance but rather to transfer power from the balance to the train wheels. The roller jewel on the balance wheel enters the fork of the pallet, driving it in one direction and causing the impulse surface of one of the pallet jewels to come into contact with one of the teeth on the escape wheel. The pallet then stops when a permanent magnet located at the apex of its fork comes into contact with one of the two magnetic banking pins, at which point either the entry or exit pallet jewel sits between a pair of teeth on the escape wheel and the pallet is then in its halted condition. As the balance swings the other way, so the process continues.

With the balance and coil safely out of the way, we can inspect the escapement. The reversed direction of operation of the movement means that the job of the pallet and escape wheel is not to measure out the power from a mainspring via the balance but rather to transfer power from the balance to the train wheels. The roller jewel on the balance wheel enters the fork of the pallet, driving it in one direction and causing the impulse surface of one of the pallet jewels to come into contact with one of the teeth on the escape wheel. The pallet then stops when a permanent magnet located at the apex of its fork comes into contact with one of the two magnetic banking pins, at which point either the entry or exit pallet jewel sits between a pair of teeth on the escape wheel and the pallet is then in its halted condition. As the balance swings the other way, so the process continues.

You may also have noticed that the escape wheel sports a second serrated click wheel at a level slightly higher than that of the escape wheel itself. This click wheel works with the retaining pawl – the thin straight spring indicated in the inset in the photo above – and its purpose is to prevent the reversal of the escape wheel when reverse torque acts upon it as a consequence of the operation of hands setting or the operation of the date driving wheel. We’ll get a better view of this in a bit once the train bridge is removed.

You may also have noticed that the escape wheel sports a second serrated click wheel at a level slightly higher than that of the escape wheel itself. This click wheel works with the retaining pawl – the thin straight spring indicated in the inset in the photo above – and its purpose is to prevent the reversal of the escape wheel when reverse torque acts upon it as a consequence of the operation of hands setting or the operation of the date driving wheel. We’ll get a better view of this in a bit once the train bridge is removed.

Next step, remove the friction spring for the sweep second pinion, followed by the train wheel bridge.

With the train wheels out of the way, we can remove the retaining pawl and ponder once more its purpose.

With the train wheels out of the way, we can remove the retaining pawl and ponder once more its purpose.

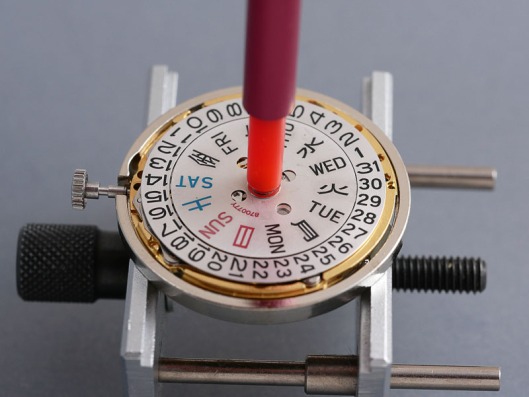

Time I think to flip the movement over and take a gander at the calendar side. We are greeted by a familiar view, noting the presence of a snap to keep the day wheel in position.

Time I think to flip the movement over and take a gander at the calendar side. We are greeted by a familiar view, noting the presence of a snap to keep the day wheel in position.

That snap caused the only significant impediment to further progress, proving remarkably resistant to my attempts to liberate it from its grip on the hour wheel post. I prevailed in the end but the snap emerged somewhat the worse for wear and will require a fresh replacement when reassembling. Dismantling of the calendar side then proceeded as follows, without further incident.

That snap caused the only significant impediment to further progress, proving remarkably resistant to my attempts to liberate it from its grip on the hour wheel post. I prevailed in the end but the snap emerged somewhat the worse for wear and will require a fresh replacement when reassembling. Dismantling of the calendar side then proceeded as follows, without further incident.

The battery contact leaves next but not before revealing further copious deposits of electrolyte product to its rear.

The battery contact leaves next but not before revealing further copious deposits of electrolyte product to its rear.

All that remains is to remove the second setting lever and its spring (which shakes off its constraints, pings off my forehead and shoots into the unknown).

All that remains is to remove the second setting lever and its spring (which shakes off its constraints, pings off my forehead and shoots into the unknown).

Armed with the unflinching optimism of the seasoned watch smith, confident that wormholes do not in fact lie in wait, ready to hoover watch parts off to infinity and beyond, I whipped out my torch, got down on my hands and knees and performed a grid search of my immediate surroundings. Five minutes invested and a glint caught my eye at the periphery of the Persian rug sitting in the middle of the room, and there lay my errant spring. Phew.

Armed with the unflinching optimism of the seasoned watch smith, confident that wormholes do not in fact lie in wait, ready to hoover watch parts off to infinity and beyond, I whipped out my torch, got down on my hands and knees and performed a grid search of my immediate surroundings. Five minutes invested and a glint caught my eye at the periphery of the Persian rug sitting in the middle of the room, and there lay my errant spring. Phew.

Before transferring all of the parts to the cleaning machine, I wanted to remove all traces of the spilled electrolyte knowing that it would not be soluble in the watch cleaning solutions. As a pre-clean then, I immersed most of the affected parts in distilled vinegar, a strategy that proved extremely effective at eradicating all traces of the electrolyte salts and preserving the finish of the movement.

With everything squeaky clean, we can swing into reverse and start to build the movement up again. In doing so, some care is required because the order of play will follow a slightly unconventional path, dictated by the slightly unusual architecture of the movement, rather than the fact that I am working largely free of guidance from any technical manuals. The first step though is straightforward enough in fitting the main setting components.

Over to the other side and that second setting lever spring is relocated with the utmost care.

Over to the other side and that second setting lever spring is relocated with the utmost care.

The location of the lever itself requires the hook of the spring to be located into the groove around the base of the vertical post that operates the electrical power switch lever (see later).

The location of the lever itself requires the hook of the spring to be located into the groove around the base of the vertical post that operates the electrical power switch lever (see later).

At this point, I would normally set about installing the gear train but the lower bearing to support the fourth wheel pinion is not yet in place (indicated by the arrow in the photo below).

At this point, I would normally set about installing the gear train but the lower bearing to support the fourth wheel pinion is not yet in place (indicated by the arrow in the photo below).

The jeweled bearing in question is located on the date dial guard and we can’t fit that until all of the other calendar parts are in place. So that is what we do next.

The jeweled bearing in question is located on the date dial guard and we can’t fit that until all of the other calendar parts are in place. So that is what we do next.

With that accomplished, we can return to the gear train, locating the escape wheel, fourth and third wheels and the sweep seconds pinion in that order.

With that accomplished, we can return to the gear train, locating the escape wheel, fourth and third wheels and the sweep seconds pinion in that order.

The train bridge comes next, topped off with the friction spring for the sweep seconds pinion, followed by the pallet and cock, and retaining pawl.

The train bridge comes next, topped off with the friction spring for the sweep seconds pinion, followed by the pallet and cock, and retaining pawl.

We appear to be coasting towards completion. Next up, the balance and coil, carefully nursed into position having first fitted the plate that sits beneath the balance.

We appear to be coasting towards completion. Next up, the balance and coil, carefully nursed into position having first fitted the plate that sits beneath the balance.

It’s all looking rather spruce. We are two steps away from proving the pudding to be worthy of the eating. The circuit is fixed into position next, and topped off with the power switch lever that forms a mechanical link between the second setting lever post and the cut-off terminal on the circuit board as well as an electrical connection to the power supply.

It’s all looking rather spruce. We are two steps away from proving the pudding to be worthy of the eating. The circuit is fixed into position next, and topped off with the power switch lever that forms a mechanical link between the second setting lever post and the cut-off terminal on the circuit board as well as an electrical connection to the power supply.

We have reached that rather nervy point at which all that effort is either rewarded or found to have been in vain. It’s time to locate a suitable battery, press it into position and see what happens.

We have reached that rather nervy point at which all that effort is either rewarded or found to have been in vain. It’s time to locate a suitable battery, press it into position and see what happens.

Well, that is rather startling. Off it goes, without so much as a by your leave, instantly accelerating up to its working speed of 28800 bph. I must say, I feel unreasonably pleased with myself.

Well, that is rather startling. Off it goes, without so much as a by your leave, instantly accelerating up to its working speed of 28800 bph. I must say, I feel unreasonably pleased with myself.

The final step is to fit the day disk, secured into position with a brand new snap.

Refitting the dial spacer, dial and hands restores to a significant extent the watch’s sense of identity.

Refitting the dial spacer, dial and hands restores to a significant extent the watch’s sense of identity.

The case is next on our agenda, this one presenting one major problem at the outset: the sourcing of a correct crystal. You will have noticed in the opening photos that the crystal is faceted, with a large central square facet surrounded by four curve-edged facets reaching to the outer diameter of the crystal’s circular edge.

The case is next on our agenda, this one presenting one major problem at the outset: the sourcing of a correct crystal. You will have noticed in the opening photos that the crystal is faceted, with a large central square facet surrounded by four curve-edged facets reaching to the outer diameter of the crystal’s circular edge.

It is also one of those confounded constructions in which the crystal itself is bonded to a metal ring which sits against a rubber gasket in the case.

It is also one of those confounded constructions in which the crystal itself is bonded to a metal ring which sits against a rubber gasket in the case.

The availability of such crystals will depend on the number of watch models sharing the same part and the rarity of those models. In this respect, we have the double whammy of a watch with a short production run and therefore thin on the ground, and one which did not share its crystal with (m)any(?) other models. In fact, a significant part of my problem was that this model does not show up at all in either of the Jules Borel or Cousins databases, nor does it appear in any of the Seiko Casing Parts catalogues in my possession. I’ve actually lost track of how I eventually managed to obtain the part number (295V05GC) but having done so, I could find no trace of it anywhere: not on eBay, Cousins, Jules Borel, Yahoo Japan nor any of the numerous smaller watch parts suppliers I have been in the habit of using. However, Instagram came to my rescue. One of my Instagram friends is a watchmaker based in the Netherlands and he offered to see if he could source the crystal I needed from his local parts supplier, and fortunately for me and my watch, he was able to do. So very many thanks to him!

The availability of such crystals will depend on the number of watch models sharing the same part and the rarity of those models. In this respect, we have the double whammy of a watch with a short production run and therefore thin on the ground, and one which did not share its crystal with (m)any(?) other models. In fact, a significant part of my problem was that this model does not show up at all in either of the Jules Borel or Cousins databases, nor does it appear in any of the Seiko Casing Parts catalogues in my possession. I’ve actually lost track of how I eventually managed to obtain the part number (295V05GC) but having done so, I could find no trace of it anywhere: not on eBay, Cousins, Jules Borel, Yahoo Japan nor any of the numerous smaller watch parts suppliers I have been in the habit of using. However, Instagram came to my rescue. One of my Instagram friends is a watchmaker based in the Netherlands and he offered to see if he could source the crystal I needed from his local parts supplier, and fortunately for me and my watch, he was able to do. So very many thanks to him!

Here is the new crystal, now fitted, with the outgoing there to contrast not only its shabby condition but also the fact that the central square facet on the old crystal is much larger than that of the new. A quick comparison with the marketing photos in the catalogue shot four photos into this entry show that the new crystal is correct and the crystal fitted to the watch as received must have been a handy substitute rather than the correct part.

Here is the new crystal, now fitted, with the outgoing there to contrast not only its shabby condition but also the fact that the central square facet on the old crystal is much larger than that of the new. A quick comparison with the marketing photos in the catalogue shot four photos into this entry show that the new crystal is correct and the crystal fitted to the watch as received must have been a handy substitute rather than the correct part.

The case is ready to receive its movement and so let us reunite them.

The case is ready to receive its movement and so let us reunite them.

This is perhaps a good point to reflect on the position these electronic movements occupied in the historical development of the wristwatch. A good opening question might be: What was the point of them? In hindsight, given the massive impact of the quartz technology that was to follow, a reasonable answer might be: a historical curiosity, a stop gap, a holding position. But at the time that they emerged onto the market in the 1960’s, it is not difficult to see how they might have been viewed as some sort of vision of the future, an example of the white heat of technology. Seiko’s marketing blurb suggesting that these were ‘for the man looking to the future’ backs that up but in order to be a sales success they needed to be something more than a marketing flimflam. They needed to offer something tangible in terms of performance and they did just that. Where the timekeeping of a mechanical watch will usually vary with the power reserve of the mainspring, an electronic watch supplies a constant power to the balance and so in principle its timekeeping should be much more consistent. There is also the added appeal that they will keep running until the battery runs flat, regardless of whether they are worn or indeed, in comparing them to an automatic mechanical movement, of how sedentary or active the wearer might be. The proof of that proposition lies in the fact that in the 2 weeks since completing the watch, it has gained a total of 12 seconds.

This is perhaps a good point to reflect on the position these electronic movements occupied in the historical development of the wristwatch. A good opening question might be: What was the point of them? In hindsight, given the massive impact of the quartz technology that was to follow, a reasonable answer might be: a historical curiosity, a stop gap, a holding position. But at the time that they emerged onto the market in the 1960’s, it is not difficult to see how they might have been viewed as some sort of vision of the future, an example of the white heat of technology. Seiko’s marketing blurb suggesting that these were ‘for the man looking to the future’ backs that up but in order to be a sales success they needed to be something more than a marketing flimflam. They needed to offer something tangible in terms of performance and they did just that. Where the timekeeping of a mechanical watch will usually vary with the power reserve of the mainspring, an electronic watch supplies a constant power to the balance and so in principle its timekeeping should be much more consistent. There is also the added appeal that they will keep running until the battery runs flat, regardless of whether they are worn or indeed, in comparing them to an automatic mechanical movement, of how sedentary or active the wearer might be. The proof of that proposition lies in the fact that in the 2 weeks since completing the watch, it has gained a total of 12 seconds.

Having now worked on one of these watches, I find myself very favourably disposed, not least for the fillip of pleasure I received when the movement sprang into action as soon as a battery was pressed into place. You may enjoy a glimpse of that experience in the following short video.

We have come to a conclusion I think. The remainder, as always, is to fit a strap or bracelet – the latter in this case – and survey the result.

These are watches that deserve to be recognized, not least for their period style and personality but also because they represent a stepping point in the evolution of horology, albeit one that is all but forgotten (or at least neglected).

These are watches that deserve to be recognized, not least for their period style and personality but also because they represent a stepping point in the evolution of horology, albeit one that is all but forgotten (or at least neglected).

Further reading

http://electric-watches.co.uk/

https://sweep-hand.org/the-x8-cosmotron/

Another fantastic read. I look forward to these more than anything else watch related. Thanks Martin!

Thanks Steve, I’m pleased to hear that 🙂

Amazing to see the transition from mechanical to quartz with Seiko pushing the boundaries of futuristic looks and design. A great read as always thank you Martin. PS How many watches do you own? (I imagine a lot from all the posts… I wonder how much wrist time you can give them all?) Thanks again. Andrew.

Thanks Andrew. The problem with futuristic styling is that it can look dated so quickly but in this case I think we can categorise it as period charm!

As to my watch collective, obviously, the answer to your question is ‘too many’! However, those watches that I find I don’t wear will eventually find themselves passed on to new owners so quite a few of the the watches that have appeared here, I no longer own.

What a fun piece to work on. Thanks for the insight and also having a go at something you hadn’t tackled before.

I do look foward to your watch fettlings.

Martin, I’ve run into this same snap ring on a 5216. I have come to a halt because I don’t want to damage the hour wheel and disk. I see the part is available at cousins, but how did you end up removing it and with what tool? Thanks very much for any assist.

Hi Dan, I am afraid that my solution was not especially elegant nor did it leave all parties unblemished! The snap itself was no longer fit for purpose and the day disk acquired a couple of marks but nothing serious. I do have a few 52 series lined up and so will need to give this some more thought before tackling them.

My removal technique was much the same as that I use to remove day disk snaps on 6309’s – i.e. gently prise the snap up and over the groove in the hour wheel, starting from the gap in the snap. As you have discovered, it proves remarkably resistant to this technique. I wonder whether it might be better to slide it off horizontally but there will be potential hazards associated with that approach in the event of slippage! If you discover a useful technique, feel free to report back.

Bravo! This strip down is fantastically helpful. My much loved Seiko Elnix is well due for a service as its 20 years since it last had one. But it still functions perfectly, gaining about 2 secs per day.

Mine is a much more conventional design with the 0702 date only movement, a flat crystal, and an elegant dial graduating from smoke at the edge to champagne in the centre. I love it!

Glad you found it helpful!

Martin,

Do you happen to know the lift angle for the Elnix ?

Even Seiko Japan couldn’t help.

Sorry Scott – no idea. The movement is a bit niche and so unlikely to feature in the usual tabulated lists of lift angles you are likely to find on the web.

Hi Martin, hope you are well?

I have managed to snag some of the watches you have moved on from Paul C, all are running great!

But my question is about the elusive crystal for the Elnix,

I have an Elnix, 0703-6010, August 1973 dial marking is, 0703-6040R

As you mentioned, very hard to source crystal for it, would you know if a genuine Seiko 295V03GC would fit this watch?

It’s close? But not sure if any good?

Thanks again for some great reading in bed..

Regards,

Ian

Hi Ian,

The problem with the V-type bonded crystals is that the frames vary quite significantly for a given notional crystal diameter. The only way to tell if any particular crystal will fit is to buy it and try but in doing so you should fully expect that it will not! None of my sources provide any casing information for any of the Elnix watches and I was only able to locate the correct crystal part number for my Elnix by pure dumb luck. Sorry not to be of more help. All the best

Martin

Ok Martin, thanks, any pointers what direction to look?

Ian

Not really. I have no insight into the codes other than the crystal diameter. As I said, I blundered into the correct part number for my Elnix. A trial and error approach could prove very expensive! Trawl Yahoo Japan for clues perhaps?

Hi Martin, very interesting read. I have recently acquired a Seiko electronic watch that you haven’t mentioned. A 3303-8120, which appears to date from December 1972. While it seems to be in very good condition mechanically it does not start with a new battery, though shaking the watch does see it running for up to 10 seconds,

If it runs briefly on a shake then that sounds as though the electronic parts may be ok and that it is the moving parts of the movement that may need a service. The only real way to be sure is to test and service.

What is the battery type and voltage?Thanks

My notes suggest AG12/386 but you will see that I fitted a 301 in the YouTube video. I am not sure now why I went for the latter – perhaps dimensions.

Hello! This was very informative as I currently have a Seiko Elnix 0702. It runs great and I don’t see any dirt or corrosion inside. However, when the watch is laying on the table for example, it makes a sort of rattling noise but the minute I move it, the noise disappears… Does yours make any kind of similar noise? Also I am not sure why, the watch seems to run slower sometimes, like it will be back 5 to 10 seconds compared to my GS 9F62, and couple of days after, is ahead… Then couple of days later it’s almost in sync or couple of seconds behind again… No idea what’s going on. Thanks!

Hi Jonatan,

The only thing that occurs to me with regard to the sound it that the watch is somehow generating some sort of resonance with something on the table top when it is in contact with the surface. And as to the timekeeping, if it is varying by plus or minus 10 seconds day to day, then I think you are probably doing ok for a watch approaching 50 years old! Electronic balance watches are subject to the same positional variation as mechanical and the rate it achieves from day to day will depend on how much time it spends face up/down, crown down/up and so on.

I would also suggest that if it has not recently been serviced, that some/all of the above may just be symptoms of its need for general maintenance and attention.

Martin

Hi! Thanks for your quick response. Is that something you could do? If you’re interested… Since you have experience with the movement. Let me know before I contact a local watchmaker! Thank you

Hi Jonatan,

No, I’m afraid not. I only work on my own watches – sorry!

I just acquired an 0703-6010 that is in great condition aside from the crystal. I can’t find one for this specific model, but do you know if the crystals would be interchangeable in the 0703 line? If not, any ideas on where to source one?

Thanks, and I really enjoy reading your adventures.

Bryce

Hi Bryce,

I’ll see what I can find in my parts catalogues when I get home. Some of the crystals are still available but supplies of the more commonly used models may well have been exhausted.

Hello again Bryce,

Apologies, but none of my casing parts guides contains information on the 0703 models and the Jules Borel site doesn’t list anything at all for your watch. Sometimes a bit of detective work can throw up the result you need (as it did with me and my 0703) but so far I’ve drawn a blank.

Glad to hear you enjoy the blog.

Martin

Hey! I finally managed to track down a watchmaker willing to work on the Elnix 0702-8020 I had. I wanted to give you an update! It ended up costing me more than the watch but it was totally worth it! Cheers

https://imgur.com/gallery/N2Ya4R5

That’s a beaut Jonathan!

Looks great!

Martin, I have enjoyed reading your articles–thank you for the write-ups and explanations. I am a collector from the U.S., but now living in Tokyo.

Cheers!

Thanks ilham. I hope live in Tokyo is treating you well, accepting our current circumstances.

Hi man, I’ve came across your article about this Elnix watch while I was trying to find a decent Elnix that I can buy. I usually only buy mechanical watches but I became obsessed with having one of these Elnix watches. As I couldn’t find anything decent I’ve decided to buy one that is worth restoring at least. I’ve managed to find a blue dial Elnix 0703 7010 on ebay. The problem that I have now is finding the right crystal. Your info was very helpful in identifying the code of the original crystal and I thank you for that . But the problem is, I can’t find it anywhere. I’ve found something on a website in Japan but the chances to get that one are quite slim I would guess. Is there any way you could help me in sourcing one of these 295V05GC crystals? To be honest I am a bit desperate at the moment. Another thing that I know it will be probably impossible to find is a bracelet like yours. But that’s another story…

Thank you!

Afraid I can’t offer any fresh leads on that crystal. I sourced mine from a watchmaker friend in the Netherlands and I think that was a one off. Your best best is probably trawling Yahoo Japan and being patient! You never know when one might pop up. Good luck!

I’ve found one on Yahoo Japan but it looks like you can’t register unless you have a Japan phone number. So I am stuck. Any ideas? 😦

You just need to register with a proxy service such as Buyee and you can then bid on auctions real time through their service. There are some sellers who won’t or can’t sell via the proxy but these are generally the small minority.

Thanks for this teardown, & the one of the EL-370, where I left a longer comment.

I do have one question : how do you recommend replacing the power cell on the Elnix? The strap has two screws, one of which goes through a hole, while the other fits into a notch. It seems as though the intent is that, after loosening the screws somewhat, the side of the strap with the notch can be worked out from under the screw, & the strap swung away. This would avoid completely removing either screw, which I would prefer to do, since they’re quite tricky to set back into place.

Only one problem : with a power cell installed, I can’t seem to flex the strap enough to get it free of the screw on the notch side. Is there a trick to this that I’m missing?

I can’t remember now what I did but I suspect I may have set the slotted end in first with the screw already in place and then held the strap down over the battery, first having set the screw through the hole in the opposing tab before tightening it down.

I keep coming back to your site and especially this particular article. Thank you for sharing your knowledge and your great writing. I have been amassing a small horde of Elnix (both 0703A and 0723A movements) from Japan. Where were you able to find the service manuals/diagrams? I’ve been looking everywhere and have only been able to find 2 physical copies on some auction sites that got scooped up before I could even place a bid or was bundled along many other manuals making it way too expensive ($250USD). I’ve been searching for 6 months for English or Japanese and no luck. Would really appreciate some guidance!

Hi Ian, as I think I mentioned in the article, I have not been able to find any service manuals for the 07xx series and so was flying blind when working on this Elnix. However, I do have the manual for the earlier 37 series and whilst the architecture and layout is completely different, the operational principles are the same and so that did provide some use in setting the scene. Sorry not to be of more help!

Ah~~ Ok thanks. I’ll keep an eye for Japanese manuals and can share some rough translations with you if I can eventually get my hands on one. They pop up for sale once every 4-5 months. I’ve seen scans of a few pages here and there on Japanese sites but nothing complete. I think I may have chosen the wrong watch to learn how to work on watches…………..=)

If you find any, then of course I’d very much welcome seeing what you have. Thanks!

I just bought a 1974 Seiko Elnix SG (Superior Grade) JDM 0723 7000 in really good condition with original bracelet. I am waiting for delivery.

I found your article very informative and would like to thank you very much for all the details and photos.

I am pleased to hear you found it useful. Thank you for the feedback.

This is an amazing story you present here!

I too am the Owner of a Seiko Elnix given to me for my 21st Birthday in 1977

it has the Blue Dial

I havr had it reoaired many times because of leaky batteries

It now sits in my watch box not working anf I wonder who could possibly help it to work again

ad I brlievr it was a very important modrl fir it’s time

Thanks Bradley. I’m glad you enjoyed the post. It is always fun to hear from people who have owned these watches from new. I hope you find someone to revive yours. All the best Martin

Seeing as the 0703 service manual (which surely has to exist) has still not materialized, this really was an invaluable article to (re)read before starting to work on a 0703-7100 myself. As it was another victim of a leaky battery, I’m very pleased with how it turned out, and the quality is astonishing considering what I paid for it.

Interestingly, although the movement is also a 0703A, the circuit board in mine is a bit different, with the big white round… thing… in yours (and most others I see online) replaced by a small black rectangular one that doesn’t protrude through the board.

I was initially a bit disappointed with the poor amplitude I got, clearly less than 200 degrees after my best efforts, but after a bit on thinking (especially considering the reverse flow of power) and tweaking, it turned out to be fairly sensitive for the pressure of the tiny clickspring on the escape wheel. Adjusting it to touch just enough to do its job and the tiniest dab of oil on the teeth, and the amplitude jumped to around 270 degrees.

Hi AJ, you make an interesting observation about the how sensitive the amplitude is to how the click spring has been set up. Thank you for that.

Hello. I have an Elnix that does not run since battery-change. It runs for a few seconds and than stops. Inside is a LR43. I have another elnix that runs fine with the LR43. I would like to get it checked and serviced, but in the netherlands i can’t find anybody who works with this type of watches. Would you check it for me or do you know somebody who can get it serviced. Regards Frank Faasen

Hello. I have an Elnix that does not run since battery-change. It runs for a few seconds and than stops. Inside is a LR43. I have another elnix that runs fine with the LR43. I would like to get it checked and serviced, but in the netherlands i can’t find anybody who works with this type of watches. Would you check it for me or do you know somebody who can get it serviced. Regards Frank Faasen

Hi Frank, I’m afraid I don’t take in any third party work and don’t know of any electronic movement experts. However, you might give Richard Askham in the UK a try. Best of luck

Martin

forgot to mention the type in last comment.

It is a 0703-7050.

Greetings, I’m not a watch smith but I am a gear head. I was magnetized by your breakdown with visuals, you made it look easy, and you’ve convinced me not to obtain one due to the crystal issue. Have you chums considered to polish out the scratches ? Daunting task but if you gentlemen have the vise to hold it would it be possible ? I have experience with automobile paint which utilizes 600-3000 grid water sanding or higher, then buffing for finish. The angles would be troublesome. Just an idea, perhaps I’m mad.

I know I would never be able to finish a crystal to a high standard using the method you suggest. The only approach for me is to source a replacement crystal.

The problem wish polishing these crystals is maintaining the angles and edges. There’s a small chance you may find a jewelry making willing to see if their diamond polishing machines can handle the crystal but it’ll be probably cheaper overall to just get a new crystal. I’ve gotten out of trying to fix my own Elnix watches now and have some crystals if you are interested. Let me know if you do. Otherwise, try looking on Japanese Yahoo auction or mercari. The yen is still a little weak at the moment so you might get a deal.

Hello great article, thanks to you I’m trying to repair an elnix but I’m not able to find the 3th wheel that I need. Any suggestions? thanks

I’d check eBay or Buyee Japan listings for “Not Working” or

“For Parts Or Repair” listings.