Tags

6217, 6218, Diver's Watches, Modified watches, Seiko, Vintage

Hot-rod verb \ˈhät-ˌrä-d\

To modify an engine to achieve higher performance

In common with many watch companies of the 1960’s and 70’s, Seiko fitted closely related versions of the same movement to a diverse selection of very different watches. The Seikomatic watches featured in recent posts here and here were powered by variants of the 62 series movements, all of which trace their lineage back to the 603 calibre which first appeared in 1960. In the dressier models, the movements were frequently gilted and well-endowed in their jewel count: upper-mid tier watches with aspirations to upwards mobility. Higher end variants of the 62 series movements found their way into sub-chronometer spec 6218 Seikomatics and chronometer spec watches such as the 39 jewel Seikomatic 6216-9000. One step further up the pecking order sat the first automatic Grand Seikos fitted with 35 and 39 jewel 6245 and 6246 chronometer movements.

The working man, however, needed something more down to earth, less ostentatious – something built for reliability, no nonsense and, well, lets face it, cheaper. The somewhat more prosaic 17 jewel 6217A played that role in the classic divers watch of that period, the Seiko 6217-8000 (62MAS) as well as in the first generation World Timers. It is somewhat ironic that 50 years later, the mid-level Seikomatics can be had for the price of a cheap day return to Kings Cross whereas a decent 62MAS could pay for a weekend for two in New York.

I’ve written about the 62MAS on two previous occasions here and here, in both cases featuring watches which were cosmetically challenged to the extent that they needed dial relumes. I like both a great deal but have kept my eye out for an example with as pristine a dial as possible, but as is my wont, as parsimoniously as possible. As it happened, I stumbled across such an example early this year and have been waiting for the opportunity to lick it into shape.

In the intervening period, I’ve also been accumulating a small assortment of tatty examples of higher-end Seikomatics, hopeful of rich pickings beneath their sorry exteriors. My cunning plan, half-formed at its genesis but taking shape over the past few months has been to construct a more refined engine in keeping with the beautiful face of this latest example of the 62MAS to cross my path, a 6217-8001 from May 1966. Here it is in the condition received

What is perhaps not necessarily evident from this head-on view is that this is certainly one of the most filth-encrusted watches I’ve purchased – so much so that the bezel was frozen solid, mired in years of solidified, well, let’s just call it gunk. However, of far greater importance is that lovely, peachy dial, its near-perfect period yellowy-green lume shining though that opaque, crazed acrylic crystal. The movement was running, but very poorly although it looked to be in good cosmetic condition.

What is perhaps not necessarily evident from this head-on view is that this is certainly one of the most filth-encrusted watches I’ve purchased – so much so that the bezel was frozen solid, mired in years of solidified, well, let’s just call it gunk. However, of far greater importance is that lovely, peachy dial, its near-perfect period yellowy-green lume shining though that opaque, crazed acrylic crystal. The movement was running, but very poorly although it looked to be in good cosmetic condition.

With the movement extracted, an unimpeded view of the dial confirms just how nice it is

With the movement extracted, an unimpeded view of the dial confirms just how nice it is

although the hour hand is rather tarnished, letting the side down just a touch.

although the hour hand is rather tarnished, letting the side down just a touch.

Those faint of heart or queasy of stomach might want to avert their gaze at this point. Here’s a view of all that lovely crud (taken from a respectful distance), gluing the bezel to just about everything in its immediate vicinity.

Those faint of heart or queasy of stomach might want to avert their gaze at this point. Here’s a view of all that lovely crud (taken from a respectful distance), gluing the bezel to just about everything in its immediate vicinity.

Now how to get that bezel off without damaging the insert? I ran the blade of a fine screwdriver around the gap between the inner edge of the insert and the outer edge of the crystal in an attempt to break the seal but in doing so I must have performed an inadvertent glazier’s coup for as I then levered the bezel free from the case, so too came the crystal top, still firmly adhered to the insert,

Now how to get that bezel off without damaging the insert? I ran the blade of a fine screwdriver around the gap between the inner edge of the insert and the outer edge of the crystal in an attempt to break the seal but in doing so I must have performed an inadvertent glazier’s coup for as I then levered the bezel free from the case, so too came the crystal top, still firmly adhered to the insert,

leaving a perfect cross-section of acrylic sitting happily between the chromed tension ring and the case lip.

leaving a perfect cross-section of acrylic sitting happily between the chromed tension ring and the case lip.

With a little gentle encouragement though, the tension ring and crystal remnant are free.

With a little gentle encouragement though, the tension ring and crystal remnant are free.

So now we come to the point where decisions need to be made. I want to upgrade the movement but I want to maintain some basic principles along the way. The upgrades I had in mind were:

So now we come to the point where decisions need to be made. I want to upgrade the movement but I want to maintain some basic principles along the way. The upgrades I had in mind were:

- a stop seconds (hacking) facility

- as many jeweled bearings as possible in the gear train

- fine regulation adjustment on the balance cock

Additionally, I wanted to fit a date only movement – not a day/date movement with the day complication removed. And finally, I wanted to achieve all of this without having to buy a chronometer spec Seikomatic, largely because of the high potential cost of doing so but also because I do not like the idea of cannibalising a high end watch for movement parts.

Where then do we begin? The higher grade date-only options from the 62 series movements include: the 394, which is an early 24 jewel incarnation of the 6205; the 395, a high grade 39 jewel version of the 394; the 24 jewel version of the 6205; the 35 jewel 6215, a chronometer spec movement, which as far as I can tell was only fitted to the 300m 6215-7000 divers watch of the period (and therefore out of the question on cost grounds alone); and the 6245, another 35 jewel chronometer movement fitted to the gorgeous Grand Seiko 6245-9000, which, again, we exclude on both cost and ethical grounds. With hacking being a pre-requisite, we can additionally discard the 394 and 6205 which leaves the 395. Given its 39 jewel-count, this movement would appear to offer an embarrassment of riches and it just so happens I have one, fairly recently acquired from the land of the rising sun.

You will notice however from the photo above that the 395 does not offer a fine adjustment facility on the balance and furthermore, this particular example has been subject to some fine tuning to the train side barrel hole

You will notice however from the photo above that the 395 does not offer a fine adjustment facility on the balance and furthermore, this particular example has been subject to some fine tuning to the train side barrel hole

which, while it looks like this may well be standard watchmakers’ practice, taints this particular train bridge for me. Nevertheless, this movement hacks and the main plate is in excellent condition and so it will therefore form the basis of the new movement build. I don’t propose to document the strip down because, by the time we get to the end of this build, we will have raided four different movements for parts, but let’s begin by comparing the 395 and 6217 main plates to see what added value we are getting from the former:

which, while it looks like this may well be standard watchmakers’ practice, taints this particular train bridge for me. Nevertheless, this movement hacks and the main plate is in excellent condition and so it will therefore form the basis of the new movement build. I don’t propose to document the strip down because, by the time we get to the end of this build, we will have raided four different movements for parts, but let’s begin by comparing the 395 and 6217 main plates to see what added value we are getting from the former:

Where the 6217 (above, right) does have jeweled bearings for the centre wheel, third wheel, escape wheel and, of course, the pallet arbor, the 395 boasts an extra 2 jewels by virtue of the Diafix fittings for the third wheel and escape wheel. These extra jewels serve to protect the lubrication of the bearings in the medium to long term rather than necessarily acting to upgrade the short term performance of the movement. In addition, the 395 has no fewer than NINE jewels distributed around the surface supporting the date wheel (see top left, above), there to ease its passage presumably and not, of course, to assist in the marketing of what was at the time one of the higher-end Seiko dress watches [smirk]. The most significant functional difference though is the recess and tapped screw hole to accommodate the hacking lever. With the foundations established, let’s begin, first with a quick appraisal of the now cleaned main plate, with diafix jewels refitted

Where the 6217 (above, right) does have jeweled bearings for the centre wheel, third wheel, escape wheel and, of course, the pallet arbor, the 395 boasts an extra 2 jewels by virtue of the Diafix fittings for the third wheel and escape wheel. These extra jewels serve to protect the lubrication of the bearings in the medium to long term rather than necessarily acting to upgrade the short term performance of the movement. In addition, the 395 has no fewer than NINE jewels distributed around the surface supporting the date wheel (see top left, above), there to ease its passage presumably and not, of course, to assist in the marketing of what was at the time one of the higher-end Seiko dress watches [smirk]. The most significant functional difference though is the recess and tapped screw hole to accommodate the hacking lever. With the foundations established, let’s begin, first with a quick appraisal of the now cleaned main plate, with diafix jewels refitted

The next step is to fit a brand new centre wheel supported by the centre wheel bridge taken from the 395, adding a further additional jewel to the jewel count in the bearing plate which supports the fourth wheel pinion,

The next step is to fit a brand new centre wheel supported by the centre wheel bridge taken from the 395, adding a further additional jewel to the jewel count in the bearing plate which supports the fourth wheel pinion,

as well as the winding stem, clutch, setting lever and setting wheel, all part of the keyless works.

as well as the winding stem, clutch, setting lever and setting wheel, all part of the keyless works.

In practice, the keyless works comes together first, then the centre wheel and bridge, followed by the (new) cannon pinion and original hour wheel from the 395 (in position in the photo above). The hour wheel from the 6217 would not have fitted for reasons detailed in one of the earlier 62mas posts here. Now we have another minor hurdle to overcome. Having discarded the train wheel bridge from the 395 because of the horseshoe impression delivered by a watch maker to reduce barrel arbor side shake, I needed a replacement. The difficulty in doing so derives from the fact that the hacking facility on the mainplate requires a matching recess in the underside of the train wheel bridge to accommodate the hacking lever. No such recess exists in the train wheel bridges from the higher jewel count 6205 and 6206’s and so instead I turned to a day/date 6218B for a donation of its flawless train wheel bridge.

In practice, the keyless works comes together first, then the centre wheel and bridge, followed by the (new) cannon pinion and original hour wheel from the 395 (in position in the photo above). The hour wheel from the 6217 would not have fitted for reasons detailed in one of the earlier 62mas posts here. Now we have another minor hurdle to overcome. Having discarded the train wheel bridge from the 395 because of the horseshoe impression delivered by a watch maker to reduce barrel arbor side shake, I needed a replacement. The difficulty in doing so derives from the fact that the hacking facility on the mainplate requires a matching recess in the underside of the train wheel bridge to accommodate the hacking lever. No such recess exists in the train wheel bridges from the higher jewel count 6205 and 6206’s and so instead I turned to a day/date 6218B for a donation of its flawless train wheel bridge.

We can see below how the 6218 bridge on the right compares with that from the 6217, left. The obvious difference is the net 4 increase in jewel count courtesy of the Diafix settings serving the third wheel and escape wheel plus the jeweled bearing for the fourth wheel. The 6217 makes do with just a single jewel serving the escape wheel. From a functional perspective, the most importance feature is the groove machined in the underside to accommodate the hacking lever.

With the 6218 train wheel bridge added to the mix, the movement really deserves a fresh mainspring

With the 6218 train wheel bridge added to the mix, the movement really deserves a fresh mainspring

With the barrel walls and base pre-lubricated, the mainspring is gently released from its holder into the barrel and the arbor fitted

With the barrel walls and base pre-lubricated, the mainspring is gently released from its holder into the barrel and the arbor fitted

Lubricate the top surface of the mainspring and arbor, on with the lid and the barrel can take its place on the main plate

Lubricate the top surface of the mainspring and arbor, on with the lid and the barrel can take its place on the main plate

together with the hacking lever, third and fourth wheels and the escape wheel. We are now ready to fit that train wheel bridge from the donor 6218B.

together with the hacking lever, third and fourth wheels and the escape wheel. We are now ready to fit that train wheel bridge from the donor 6218B.

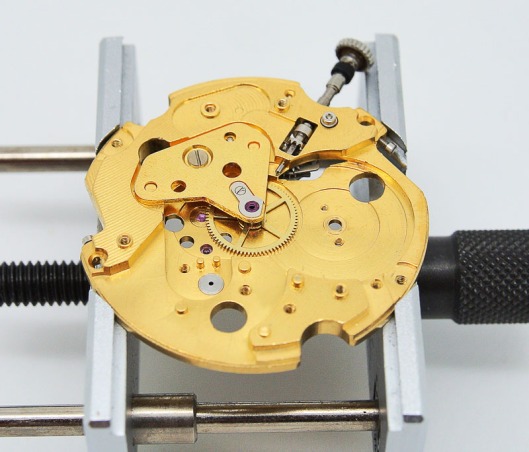

At this point, we check that all of the train wheels run smoothly by applying a bit of torque from the barrel. Lubricate the pallet jewels and then fit the pallet, pallet bridge and then, in place of the balance from either the original 6217 or the 395, I’ve opted for the balance from the 6218 which comes with a fine adjuster to help tweak the regulation with just a little bit more precision.

At this point, we check that all of the train wheels run smoothly by applying a bit of torque from the barrel. Lubricate the pallet jewels and then fit the pallet, pallet bridge and then, in place of the balance from either the original 6217 or the 395, I’ve opted for the balance from the 6218 which comes with a fine adjuster to help tweak the regulation with just a little bit more precision.

It is worth pausing to observe that the Diashock cap jewel in the 6218 balance is taller than that used in the 6217 because of the extra height of the Diashock setting required by the fine-setting lever on the top of the balance.

It is worth pausing to observe that the Diashock cap jewel in the 6218 balance is taller than that used in the 6217 because of the extra height of the Diashock setting required by the fine-setting lever on the top of the balance.

Returning to the calendar side, we can refit the remaining calendar parts, most of which from the 395 with the exception of the hour wheel and washer and the calendar plate, all of which from the 6217.

Returning to the calendar side, we can refit the remaining calendar parts, most of which from the 395 with the exception of the hour wheel and washer and the calendar plate, all of which from the 6217.

We are now ready to fit the dial

We are now ready to fit the dial

Before the hands go on, I wanted to sort out the tarnishing on the hour hand

Before the hands go on, I wanted to sort out the tarnishing on the hour hand

The darkening of the lume around its periphery may look a bit unpleasant at this level magnification but it is barely noticeable at normal magnification. With that done, case ring on

The darkening of the lume around its periphery may look a bit unpleasant at this level magnification but it is barely noticeable at normal magnification. With that done, case ring on

followed by the hour and minute hands

followed by the hour and minute hands

On the home straight now, with the case cleaned

On the home straight now, with the case cleaned

fitted with the original tension ring, the mid-case is ready to receive the movement

fitted with the original tension ring, the mid-case is ready to receive the movement

The original crown was looking a bit sorry for itself and needless to say, the gasket long since hardened and no longer up to the job. A new crown, with a nice supple gasket takes its place

The original crown was looking a bit sorry for itself and needless to say, the gasket long since hardened and no longer up to the job. A new crown, with a nice supple gasket takes its place

This view from the rear of the new crown shows why the gaskets are not easily replaceable

This view from the rear of the new crown shows why the gaskets are not easily replaceable

A dab of Locktite on the end of the tapped end of the stem and we can attach the new crown

A dab of Locktite on the end of the tapped end of the stem and we can attach the new crown

lubricate the gasket and stem and refit to the case

lubricate the gasket and stem and refit to the case

The bezel insert looks pretty good, in spite of a couple of small nibbles of corrosion on the inner edge, and I think worth preserving. The lume in the pip had turned black though so out it came

The bezel insert looks pretty good, in spite of a couple of small nibbles of corrosion on the inner edge, and I think worth preserving. The lume in the pip had turned black though so out it came

to be replaced by some fresh stuff

to be replaced by some fresh stuff

The retaining spring was dirty but otherwise in excellent condition

The retaining spring was dirty but otherwise in excellent condition

and so with it cleaned and back in position, the bezel snapped back onto the case with a satisfying click

and so with it cleaned and back in position, the bezel snapped back onto the case with a satisfying click

The last but one step is to reassemble the automatic framework

The last but one step is to reassemble the automatic framework

The jewel count stands at 33. The main plate accounts for 17 (9 under the date wheel, 1 for the centre wheel, 4 Diafix jewels, 1 for the pallet and 2 in the Diashock setting); the centre wheel bridge accounts for 2; the pallet fork accounts for 2 and its cock for 1; balance accounts for 3 (impulse jewel plus the Diashock setting); the train wheel bridge has 6 (4 Diafix jewels, 1 for the fourth wheel and 1 for the lower pivot of the transmission wheel) and the autowinder 2.

The jewel count stands at 33. The main plate accounts for 17 (9 under the date wheel, 1 for the centre wheel, 4 Diafix jewels, 1 for the pallet and 2 in the Diashock setting); the centre wheel bridge accounts for 2; the pallet fork accounts for 2 and its cock for 1; balance accounts for 3 (impulse jewel plus the Diashock setting); the train wheel bridge has 6 (4 Diafix jewels, 1 for the fourth wheel and 1 for the lower pivot of the transmission wheel) and the autowinder 2.

As far as I can tell the jeweling of what we’ve ended up with is the same as the 395 which claims 39 jewels. By my reckoning 17+2+2+1+3+6+2=33 and 33≠39. So where are the additional 6 jewels claimed by the 395? After a fair bit of detective work I think I’ve established that 6 jewels allegedly sit within the bearings of the autowinder. It is not at all clear whether this claim implies that the bearings themselves are ruby or that there is some additional jeweling within ball-bearing housing. Either way, even if they were present when my 395 emerged from the factory, I cannot be sure that the bearing has not been replaced at service in the past and in any case, I opted to use the automatic framework from the original 6217A. This means that a jewel count of 33 in this application is indisputable (not withstanding the slightly questionable value of 9 of them!). It seems fitting therefore to cap this latest endeavor with a suitable rotor:

I am not entirely convinced that this choice of rotor presents us with the best aesthetic option but if we want to trumpet the presence of 33 jewels, then it is this or nothing. With a fresh case back gasket in place, the movement regulated and showing amplitude of 275 degrees at full wind, I am happy to pronounce this one finished.

I am not entirely convinced that this choice of rotor presents us with the best aesthetic option but if we want to trumpet the presence of 33 jewels, then it is this or nothing. With a fresh case back gasket in place, the movement regulated and showing amplitude of 275 degrees at full wind, I am happy to pronounce this one finished.

Excellent!, what a great project, the 62MAS is such a great piece to wear and knowing it has a souped up motor under the hood must be very satisfying.

Awesome. This would obviously be frowned upon by many, but I think it is all down to personal choice, and I would have no problem doing the same thing.

Maybe should have added barrel jewels though as they would serve more purpose than those date dial jewels!!

Any modifications under the hood can be reversed. I still have the original movement and if the mood strikes, I can convert it back. Nothing I have done is irreversible. Having said that, everything that I do with my watches is born from my natural inclination to experiment and to then use that process to learn. I would also emphasise that all of the watches that I feature here are mine and therefore all expressions of my personality. I buy them, and repair them for me to use and enjoy every day as watches.

The issue you raise though also calls to mind a post I saw recently on a watch forum from the original owner of an Omega PloProf who 40 years after buying his watch new from an Omega AD in Rome, sent off an application to Bienne for an “Extract from the Archives” to help value his watch. They replied to say that they were unable to complete the process because the movement featured a barrel bridge from a 1001 where the original watch would have been fitted with a 1002 movement. He had had the watch serviced just once at Bienne and so it was they who must have substituted the replacement part from an incorrect calibre, an act which then resulted in them refusing to authenticate his watch on the grounds that it was no longer original!

As to your suggestion about jewelled barrel holes, I very much wanted to achieve this – indeed I even bought a new 6216 train wheel bridge – but this would need to have partnered with a mainplate from a 6216, 6215 or 6245/6. All of these calibres feature only in high end chronometers, and if modifying the movement of a 62MAS is sacrilegious, then breaking a 60’s Grand Seiko for the sake of its mainplate is a cardinal sin! Still, maybe one day I’ll track down a ruined watch and give it a try.

Omega: ouch! Gotta feel for the owner..

Barrel jewels: Could you not drill and ream the 395 mainplate to accept the lower jewel? Whilst far from original, it could be seen as a “repair”, one of a higher standard than the “horseshoe” you found on the bridge.

I totally understand where you are coming from with the statement:

“everything that I do with my watches is born from my natural inclination to experiment and to then use that process to learn. I would also emphasise that all of the watches that I feature here are mine and therefore all expressions of my personality. I buy them, and repair them for me to use and enjoy every day as watches.”

Look forward to reading more of your watch posts.

As far as drilling the mainplate to accept a barrel jewel, I am simply not there yet. I am not a watchmaker and the investment in tools necessary to be able to do what you suggest is probably not justified at the moment. On average, I plod my way through one project watch per month and at that rate I don’t encounter situations often enough where a lathe and staking tool would be indispensable. In time, maybe, but at the moment, probably not.

A fantastic job Martin! Please can you reveal what you used to clean the tarnish from the hour hand? It looks much improved after cleaning.

Thanks,

Mark

I used a piece of soft absorbant paper wrapped tightly around a pair of tweezers and then lightly pressed into a cape cod cloth to take up some of the cleaning solution. You need of course to be very careful not to contaminate the lume with the solution. There is also the very real danger that you remove too much of the nickel plating to reveal the brass underneath. So slow and steady is the right approach.

Thanks for the information Martin!

Mark

Pingback: 33石 | Adventures in Amateur Watch Fettling

Love the final result! Can you let me know what the mainspring dimensions are as I have a 62mas with a broken mainspring. Thanks!

The mainsprings are obsolete now but the part number (401610) is shared with numerous other 62series movements and so you might source one from a scrap 6206 or the like. Cousins UK suggest that the GR2533X is a correct replacement but I am not convinced myself – they seem on the short side and the bridle is not attached in the same way. Anyway, to answer your question, my crude measurements suggest 1.05mm high, 0.11 mm thick and somewhere in the region of 360mm long.

Hey Martin, thanks for getting back to me! Okay ill get a donor movement and get the part from there.

Hi Martin, I got a pretty beat up seiko 5717-8990 one button chrono and my local watchmaker won’t go near it. Could this be something you could do and feature at the blog? Please contact me at andreas.fet@skanska.no in case.

anyway, love your blog. True inspiration!

I’ve got a couple of slightly tatty 5717’s lined up for attention at some point so watch this space! I’ll email you separately with advice on what to do with your watch.

Hello,

You’ve done a wonderful job. Would you accept to restore my Seiko 6217 ? And make the same miracle ?

Tell me

thanks

sincerely

I’m sorry, but I am not a professional watchmaker. This is just my hobby and I only work on my own watches.

I am a watchsmith in Colorado – when you have a moment, if you could contact me, I would very much appreciate it – I have an inquiry / request. Spencer

Hi Spencer, I’ll contact you over the weekend.

Beautiful work very impressive this one tops the sla017 everyday! Im just getting started in the hobby I’m getting ready to start a recreation of the same watch for the ridiculous prices people are asking it’s easier to just build one yourself or restore one nicely done!

Thanks!